Motor size

|

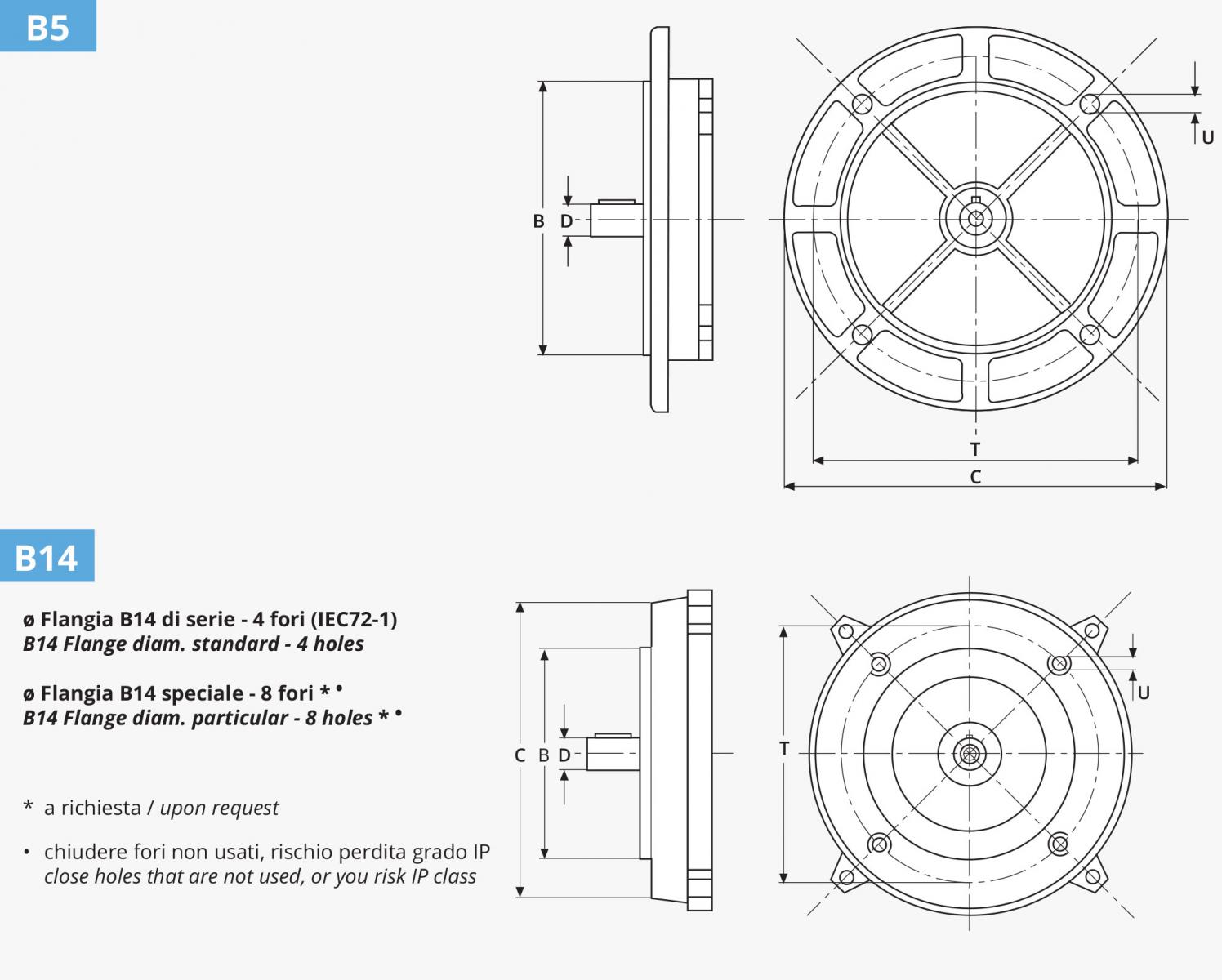

Norma

|

Shaft diam. |

B5 Flange diam. |

B14 Flange diam. |

||||||

D |

U* |

C |

T |

B |

U |

C** |

T |

B |

||

|

50 |

IEC 56 Standard |

9 |

- |

- |

- |

- |

- |

80 |

65 |

50 |

|

56 |

IEC 56 Standard |

9 |

7 |

120 |

100 |

80 |

M5 |

80 |

65 |

50 |

|

IEC 63 |

11 |

- |

- |

- |

- |

M5 |

90 |

75 |

60 |

|

|

IEC 71 |

14 |

- |

- |

- |

- |

M6 |

105 |

85 |

70 |

|

|

63 |

IEC 56 |

9 |

7 |

120 |

100 |

80 |

M5 |

90 |

65 |

50 |

|

IEC 63 Standard |

11 |

9,5 |

140 |

115 |

95 |

M5 |

90 |

75 |

60 |

|

|

IEC 71 |

14 |

- |

- |

- |

- |

M6 |

105 |

85 |

70 |

|

|

IEC 80 |

14 |

- |

- |

- |

- |

M6 |

125 |

100 |

80 |

|

|

71 |

IEC 56 |

9 |

7 |

120 |

100 |

80 |

- |

- |

- |

- |

|

IEC 63 |

11 |

9,5 |

140 |

115 |

95 |

M5 |

105 |

75 |

60 |

|

|

IEC 71 Standard |

14 |

9,5 |

160 |

130 |

110 |

M6 |

105 |

85 |

70 |

|

|

IEC 80 |

19 |

- |

- |

- |

- |

M6 |

120 |

100 |

80 |

|

|

IEC 90 |

19 |

- |

- |

- |

- |

M8 |

140 |

115 |

95 |

|

|

80 |

IEC 63 |

11 |

9,5 |

140 |

115 |

95 |

- |

- |

- |

- |

|

IEC 71 |

14 |

9,5 |

160 |

130 |

110 |

M6 |

120 |

85 |

70 |

|

|

IEC 80 Standard |

19 |

11,5 |

200 |

165 |

130 |

M6 |

120 |

100 |

80 |

|

|

IEC 90 |

24 |

11,5 |

200 |

165 |

130 |

M8 |

140 |

115 |

95 |

|

|

IEC 100/112 |

24 |

- |

- |

- |

- |

M8 |

160 |

130 |

110 |

|

|

90 |

IEC 71 |

14 |

9,5 |

160 |

130 |

110 |

- |

- |

- |

- |

|

IEC 80 |

19 |

11,5 |

200 |

165 |

110 |

M6 |

140 |

100 |

80 |

|

|

IEC 90 Standard |

24 |

11,5 |

200 |

165 |

130 |

M8 |

140 |

115 |

95 |

|

|

IEC 100/112 |

28 |

- |

- |

- |

- |

M8 |

160 |

130 |

110 |

|

|

100 |

IEC 71 |

14 |

9,5 |

160 |

130 |

110 |

- |

- |

- |

- |

|

IEC 80 |

19 |

11,5 |

200 |

165 |

130 |

- |

- |

- |

- |

|

|

IEC 90 |

24 |

11,5 |

200 |

165 |

130 |

M8 |

160 |

115 |

95 |

|

|

IEC 100/112 Standard |

28 |

14,5 |

250 |

215 |

180 |

M8 |

160 |

130 |

110 |

|

|

IEC 132 |

28 |

- |

- |

- |

- |

M10 |

200 |

165 |

130 |

|

|

112 |

IEC 90 |

24 |

11,5 |

200 |

165 |

130 |

- |

- |

- |

- |

|

IEC 100/112 Standard |

28 |

14,5 |

250 |

215 |

180 |

M8 |

160 |

130 |

110 |

|

|

IEC 132 |

38 |

- |

- |

- |

- |

M10 |

200 |

165 |

130 |

|

|

132 |

IEC 100/112 |

28 |

14,5 |

250 |

215 |

180 |

- |

- |

- |

- |

|

IEC 132 Standard |

38 |

14,5 |

300 |

265 |

230 |

M10 |

200 |

165 |

130 |

|

|

IEC 132 |

38 |

14,5 |

300 |

265 |

230 |

- |

- |

- |

- |

|

|

160 |

IEC 132 |

38 |

18,5 |

300 |

265 |

230 |

- |

- |

- |

- |

|

IEC 160 Standard |

42 |

18,5 |

350 |

300 |

250 |

M12 |

250 |

215 |

180 |

|

|

180 |

IEC 180 Standard |

48 |

19 |

350 |

300 |

250 |

* |

* |

* |

* |

|

200 |

IEC 200 Standard |

55 |

19 |

400 |

350 |

300 |

* |

* |

* |

* |

* ± 0,5 Tollerance

** It may be subject to change, since it’s a rough value

Balancing factor of rotary parts

On request rigid rotary parts by Neri are dynamically balanced per the standard ISO 1940, 1st part, grade G 6.3.

Tropicalization and condensation drainage holes (per CEI EN 60034-1 / IEC 34-1)

If the motors are installed outdoors or in high-humidity areas >60% (R.H.), the windings may be tropicalized upon request by cold painting with products having high water-repellent qualities, to protect the motor from condensation penetrating into the insulating materials and thereby avoiding damage to the insulating seal.

Also upon request, condensation drainage holes may be provided, closed with caps to be removed once the motor is installed.