Inverter motors (series IN)

From a mechanical standpoint, given the grade G6.3 rotary balance per ISO 1940-UNI 4218, when it’s necessary, in the defluxing area it is possible to achieve approximately 3 times the rated motor speed without rotor-stator contacts. A steel insert is provided in the bearing slot that prevents radial movement by the outer ring with a fair degree of security (at discretion of technical office).

In this type of motor, the bearing is pre-charged with an appropriate elastic ring that eliminates residual mechanical clearance within the bearing itself.

As our row radial ball bearings are still able to turn without problems for the sizes we use at rotation speeds around 10,000 rpm, this is additional insurance of long motor life and low noise levels.

From an electrical standpoint, we also wish to point out that motors are built with special dual- layer and shortened-pitch windings for the pur pose of eliminating undesired torque harmonics and satisfy the need for variable-speed controls.

Low-leak magnetic sheet metals are always used with a favorable ratio (stator slots/rotor slots). Special, reinforced insulation systems are used.

Generally speaking, it is possible to deflux approximately 2 times with this type of motor while keeping the rated power constant (2p - 6000 rpm).

This holds for 2- and 4-pole motors powered at the maximum rated star voltage Y.

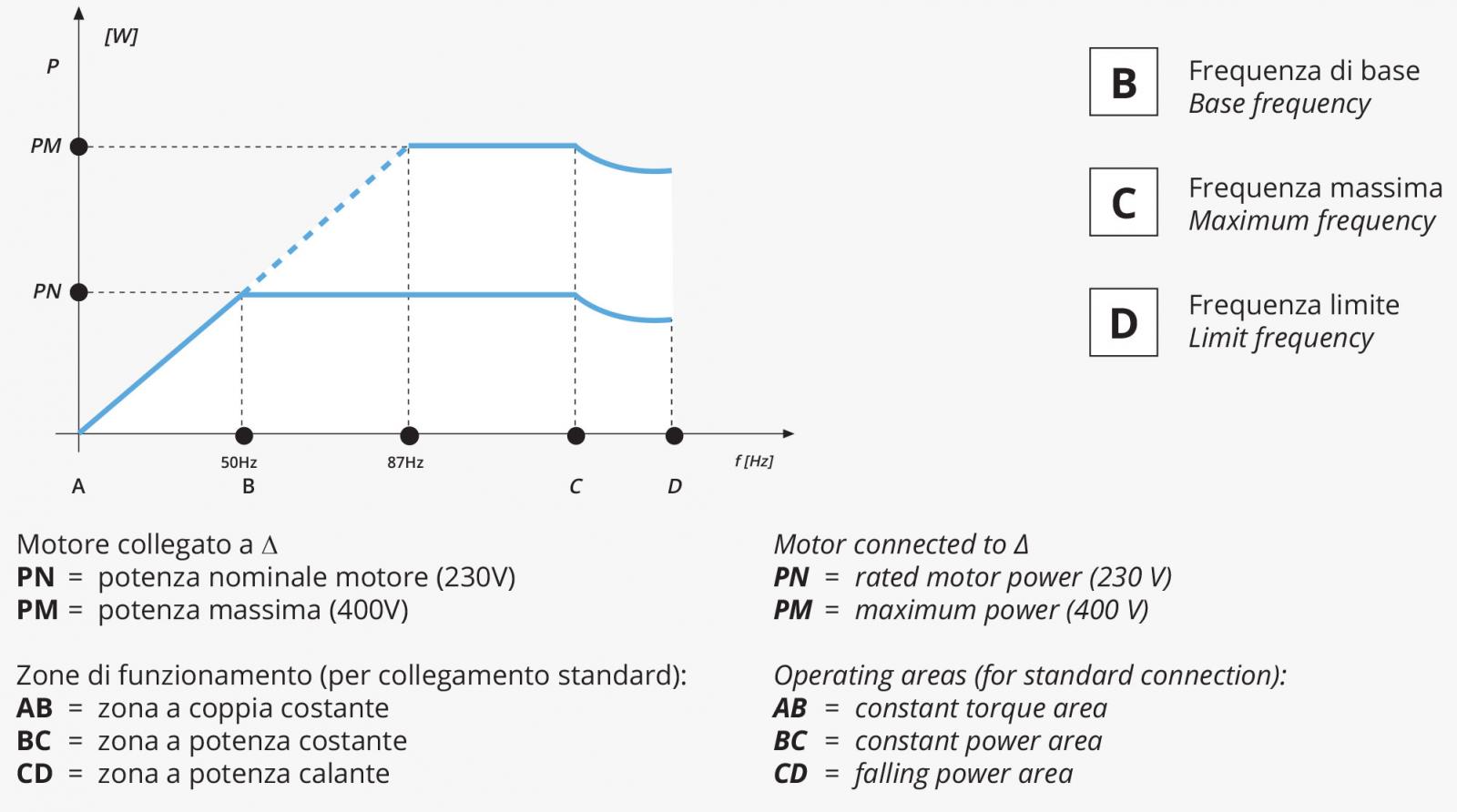

This type of motor may also be used connected to Δ (and powered by the inverter to achieve a constant rated torque at the rated star voltage Y – see figure below), with thermal duty control.

Example:

a 230V/400V/50 Hz motor is connected to Δ and taken to 400V/87 Hz at constant torque.

The available powers are more or less those listed in the catalogue. If the motor operates below 50 Hz, or with specifications other than the rated listings, power cooling is required.

Single-phase motors with high starting torque

These are motors with devices for the purpose of connecting a starting capacitor in parallel with the run capacitor, which is shut off automatically once the motor is started and measures various parameters based on the device in question. The drive torque that may beachieved during starting [Nm] is comparable to that of an equivalent three-phase motor.

Electronic capacitor (ME)

This is a timed electronic device built into the housing of an impregnated-paper capacitor.

This device starts a timer when the motor is powered, when the starting capacitor is parallel to the run capacitor; after a certain period of tie, the timer disconnects the starting capacitor to achieve a high starting torque, allowing startstop cycles every 6 seconds.

Klixon (MA)

This is an ampere relay which overcomes the force of an antagonist spring when the starting torque is high, working through a coil and mobile armature with electrical contact, to connect the starting capacitor parallel to the run capacitor.

When the motor has started the absorbed current drops and the antagonist spring is then able to overcome the electromagnetic force of the coil, thereby disconnecting the starting capacitor.

This device is available in various ampere capacities and is approved per UL and CSA standards.

Centrifugal circuit breaker (MC)

This is a highly stable device, as it detects the rpm of the motor. It consists of a rotary part keyed to the motor shaft, a duly insulated electrical part keyed to the rear motor shield, and an aluminum cap for mechanical protection, with sealing gaskets that ensure an IP 55 rating for the unit.

Only NERI can offer complete motor protection with centrifugal circuit breaker at IP 55 through an aluminum cap (on request). Without protection cap. (standard)

Internal centrifugal circuit breaker (except IEC 100).

This device has a normally closed spring-loaded contact.

When the motor begins to turn, the centrifugal force acts on two masses rotating on the shaft and exerts a force that overcomes the opposition of the spring once the rated rpm is reached.

This opens the contact and disconnects the starting capacitor used to achieve the high starting drive torque.

It may be approved by UL and CSA standards (upon request).